Product Quality Control

Transformers are sent to the next procedure by making both physical and electrical measurements at all stages of production. It is not possible to complete the process without the measurement, control and approval of production quality control personnel. Possible problems and malfunctions are investigated and revealed at the earliest possible stage.

Tests and measurements applied for semi-finished products:

• Size measurements

• Conversion rates measurements

• Insulation Resistance Measurements

• DC resistance measurements

• Leak checks

Routine tests of all transformers are performed and reported to all transformers after the production phases are completed, and some tests are performed again, some for the first time. Transformers that pass all tests successfully can be OK.

Routine Tests for Transformers:

• Measurement of winding resistance

• Measurement of voltage conversion ratio and control of voltage vector phase shift

• Measurement of short-circuit impedance and loss in load

• Measurement of no-load loss and current

• Dielectric routine experiments

- Induced voltage test

- Applied voltage test

• Insulation resistance measurement

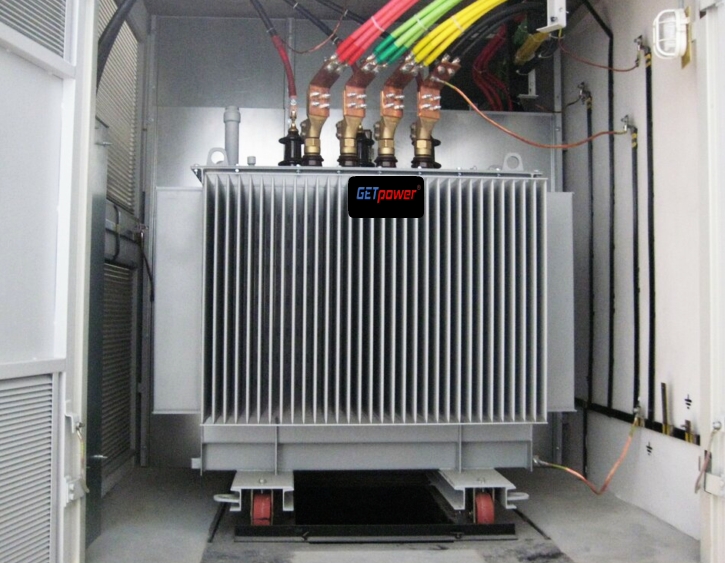

Paint :

Covers and boilers are cleaned and dried with special chemicals before painting. The first coat of primer paint, which is protected against corrosion, has a high adhesion rate and is durable, is applied. After lining, the boilers are subjected to drying process. After drying, 2 or 3 layers of special topcoat paint is applied on the primer to meet the paint thickness demand of the customer. Top coat paint color is used as RAL 7033 or RAL 9006 (can be changed according to customer demand).

English

English  Türkçe

Türkçe